Hello, my name is Stephen Simantiras and I am an Industrial designer from Morristown, NJ. I love designing and building a new Halloween costume every year that challenges my skills and knowledge of materials and different processes. Consequently, here is how I came to make this Yukon Cornelius costume.

Growing up during the Christmas season meant many things in my home. Aside from family, food, Santa and singing carols were getting to watch all my favorite Christmas shows. Out of all, I couldn’t wait to watch Rudolph the Red Nosed Reindeer. I was always fascinated with clay-mation process and how flawlessly these small characters came to life on the screen.

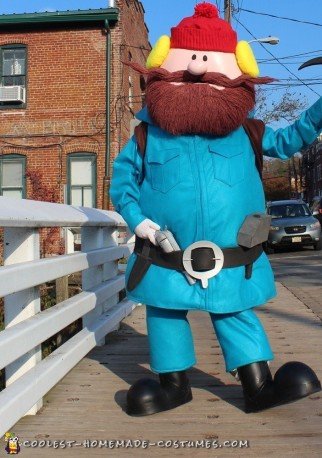

Making my Yukon Cornelius Costume

Yukon was made through a variety of processes. Prior to construction, all components were scaled to fit my proportions using CAD and Adobe Illustrator. From here I used these drawings to make templates which would further assist in the development of the form.

The head was a combination of processes. The main volume was carved from insulation sheet foam, sanded, spackled and covered in cast urethane plastic. From here it was sanded, primed and painted. The beard was made of painted faux fur. His mustache was made the same but reinforced with wire and spray adhesive to keep the form. In addition, his hat was a custom sewn polar fleece cap. Finally, there were two fans embedded in the suit to reduce heat (and it worked great!).

In conclusion, the whole project took about 144 hours to make. It started on October 3rd and took 18 days to create!

I hope you enjoy my creation!